Can You Explain The Difference Between A Rip Cut And A Crosscut On A Table Saw?

Precision – that’s the magic word in woodworking. It’s the fine difference between a good piece and an excellent piece. The table saw, a woodworker’s best friend, enables two crucial cuts – the rip cut and the crosscut. While they might seem similar to the untrained eye, they yield very different results and are used in different situations.

What are Rip Cuts?

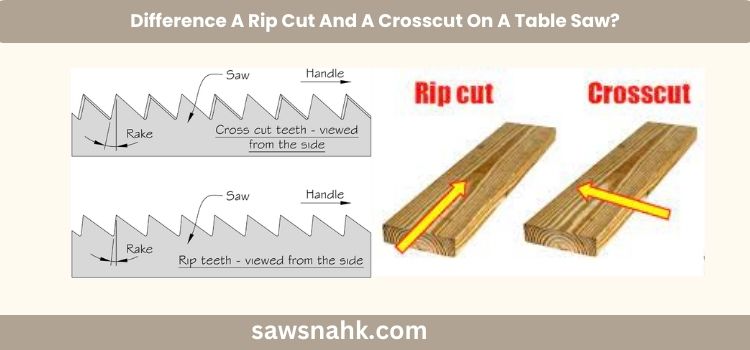

Imagine a cut that runs parallel to the wood grain, modifying the wood’s width rather than its length. This is what we call a rip cut. By altering the wood’s width, it can be tailored to fit specific requirements, making it narrower or wider as needed.

Picture this: you have a broad hardwood plank that you need to convert into narrower strips for a hardwood flooring project. A quick and effective solution? Performing a rip cut on your table saw.

What are Crosscuts?

In contrast, crosscuts are performed perpendicularly to the grain of the wood. They are used when the length of a board needs to be reduced or when crafting precise pieces with definitive dimensions.

Imagine constructing a window frame with a long wooden strip. The strip needs to be cut accurately to length to ensure a snug fit. Using a crosscut method on your table saw will allow for such precision.

The Key Difference: Direction and Grain Orientation

So, how exactly do rip cuts and crosscuts differ?

The primary difference lies in the direction of the cut relative to the wood grain. In rip cuts, the blade moves parallel to the grain, aligning with the wood’s natural fibers. This results in longer, continuous wood fibers.

On the other hand, crosscuts involve the blade moving perpendicularly to the wood grain, cutting across the fibers. The blade’s position at a right angle to the grain allows for clean, precise cuts, yielding shorter, more disjointed wood fibers.

The Impact on Appearance and Structural Characteristics

Rip cuts often show a more uniform grain pattern, providing a smooth, flowing appearance that accentuates the wood’s natural beauty. This makes rip cuts the preferred choice for projects like furniture with exposed edges.

Conversely, crosscuts create a rougher surface due to the shorter wood fibers in the cut area. Although this might add to the visual appeal, it is beneficial for joinery because the shorter fibers facilitate better glue adherence, enhancing the strength of the wooden pieces.

The Effect on Splinters & Tear-Out

Rip cuts are less likely to cause splinters and tear-out at the edge compared to crosscuts. As crosscuts cut against the grain, they are more likely to cause shards or tear out, particularly when working with softer woods.

Making the Choice: Rip Cuts or Crosscuts?

Knowing when to use rip cuts or crosscuts can significantly influence the success of your woodworking project. It all comes down to understanding the properties of each cut and deciding based on the desired appearance and application.

Safety Tips for the Workshop

While using a table saw, always use a sharp blade to reduce the chance of injuries and accidents. Ensure your fence is correctly aligned for accurate and straight cuts. Utilize push sticks or featherboards to guide the wood safely through the saw, preventing binding or kickback. And of course, always protect your eyes from flying debris or splinters.

If you’re unsure about what type of cut to make, start with a crosscut. This type of cut typically produces fewer splinters and tear-outs, resulting in cleaner results.

Conclusion

Understanding the differences between rip cuts and crosscuts can significantly enhance your woodworking skills. While both are made on a table saw, their impact varies due to how they orient the wood grain.

Rip cuts run parallel to the grain, yielding longer, continuous wood fibers. These cuts are perfect for resizing lumber and maintaining consistent thickness. On the other hand, crosscuts, made across the grain, produce shorter, disrupted wood fibers, ideal for achieving precise lengths and creating clean cuts.

So, choose your cuts wisely, and create your woodworking masterpieces with precision and finesse!

FAQ’s

When should I use a rip cut or a crosscut in my woodworking projects?

When you want to make boards smaller or larger or create a consistent thickness, rip cuts are the way to go. Crosscuts are best for precise lengths, uniform pieces, or cutting against the grain to prevent tear out.

Are any specific projects requiring only rip cuts or crosscuts?

Some projects require only one type of cutting. Construction of hardwood flooring, for example, may need rip cuts to resize boards. Crosscuts are used to get precise angles and lengths when creating picture frames.

Can I use the same blade for both rip cuts and crosscuts?

Yes, You Can Use The Same Blade For Both Types Of Cuts. For Optimal Results, Use A Blade That Can Be Used For Both Rips And Crosscuts.