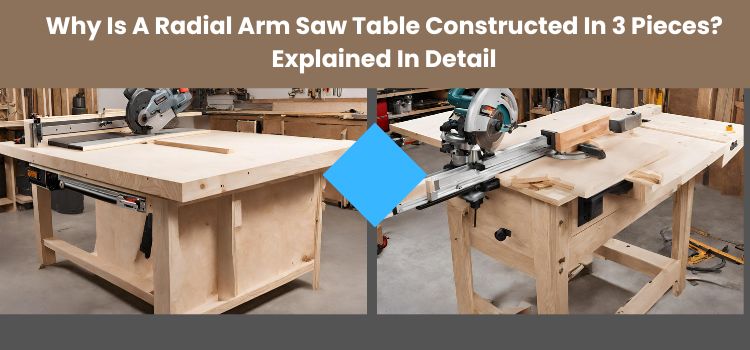

Why Is A Radial Arm Saw Table Constructed In 3 Pieces? Explained In Detail

In the realm of woodworking, mastery not only involves the skill of the artisan but also the quality and functionality of the tools employed. One such tool that stands as a linchpin in woodworking is the radial arm saw.

In this blog post, we will delve deep into the world of radial arm saws, focusing on the three-piece construction of the radial arm saw table and why this design is critical in woodworking.

Brief Introduction to Radial Arm Saws

Radial arm saws are central to woodworking, offering versatility and precision in cutting various materials. The centerpiece of this tool is its table, designed meticulously in three parts to facilitate different woodworking tasks with great efficiency and safety.

Why is a radial arm saw table constructed in 3 pieces? Top 5 Reasons

Understanding the three-piece construction of the radial arm saw table is pivotal as it brings a plethora of benefits to woodworking. Let’s explore why this construction is highly favored:

1. Stability and Rigidity

The foundational advantage of the three-piece construction is the enhanced stability and rigidity it grants during operations. This design significantly minimizes vibrations, thereby ensuring that each cut is accurate and reducing the risk of accidents due to unstable operations.

2. Flexibility and Adjustability

The dynamic nature of woodworking tasks necessitates a table that can be adjusted easily to cater to various workpieces. The three-piece table permits easy adjustments in width and depth, paving the way for undertaking complex woodworking tasks including bevel cuts with great finesse.

3. Ease of Maintenance and Replacement

A standout feature of this construction is the ease of maintenance and replacement it offers. If one part of the table gets damaged, it can be replaced individually, thus saving both time and resources.

Moreover, this segmented approach simplifies the cleaning process, as each part can be accessed and serviced separately.

4. Portability and Storage

For woodworkers grappling with limited workshop space, the three-piece construction emerges as a savior, allowing for easy disassembly and compact storage. This feature ensures that you can maintain a spacious workshop without compromising on the quality of your tools.

5. Safety Features

Safety remains paramount in woodworking. This design fosters safety through the integration of features such as blade guards and anti-kickback devices.

By reducing the potential for accidental contact with the blade, it significantly decreases the risk of injuries, ensuring a safer working environment.

Conclusion

In conclusion, the three-piece construction of the radial arm saw table stands as a monumental advancement in woodworking, underlining stability, flexibility, and safety in operations. The thoughtful integration of this design not only makes woodworking tasks more manageable but also ensures a safer and more efficient working environment.

As you consider adding a radial arm saw to your woodworking arsenal, remember the manifold benefits this three-piece construction brings to the table. It is more than just a tool; it is an investment in quality, precision, and safety, promising to elevate your woodworking projects to new heights of excellence.

FAQS

Why is the radial arm saw different from the table saw?

The radial arm saw features a motor mounted on a horizontal arm above the work surface, offering versatility in cuts; a table saw has a blade protruding from the table, specializing in straight, precise cuts.

What are the disadvantages of a radial arm saw?

Disadvantages include a larger footprint, complexity in setup and adjustments, a steep learning curve, and often being more dangerous compared to table saws due to potential kickbacks.

How do you assemble a radial arm saw?

To assemble, secure the arm and motor to the yoke, attach the yoke to the column, fix the column to the base, then align and calibrate all components ensuring accuracy and safety; consult the manual.

What are the rules for a radial arm saw?

Rules include: securing the material properly, maintaining a safe distance between the blade and hands, using appropriate safety gear, regularly checking the alignment of the saw, and following the manufacturer’s safety guidelines.

Is it safe to rip on a radial arm saw?

While it’s possible to rip material using a radial arm saw, it generally entails higher risk compared to a table saw; ensuring proper setup and utilizing safety measures is vital.